Introduction: Rethinking Corn Stalks as an Energy Resource

Corn stalk pellet machine technology is transforming how agricultural residues are utilized, offering an efficient way to convert corn stalk waste into valuable biomass fuel. Each year, corn farming generates massive amounts of stalks that are often burned or discarded, leading to resource waste and environmental pressure. By pelletizing corn stalks into dense, uniform fuel, producers can significantly improve storage efficiency, transportation convenience, and overall energy utilization.

As biomass energy continues to gain global attention, corn stalk pellets are increasingly used in industrial heating systems, biomass power plants, and commercial fuel markets, making pellet production a practical and scalable solution for agricultural regions.

Corn Stalk Properties and Pelletizing Challenges

Corn stalks differ from wood residues and energy grasses in several ways. They are fibrous, lightweight, and contain varying moisture levels depending on harvest conditions. These characteristics make pelletizing possible, but only when the process is carefully designed.

Common challenges include uneven particle size, fluctuating moisture content, and high fiber toughness. Without proper preparation, pellet durability may suffer. This is why professional pelletizing systems are essential when working with corn stalk biomass.

(Related Post: https://biomasspelletizer.com/corn-stalk-pellet-machine/)

Why a Corn Stalk Pellet Machine Matters

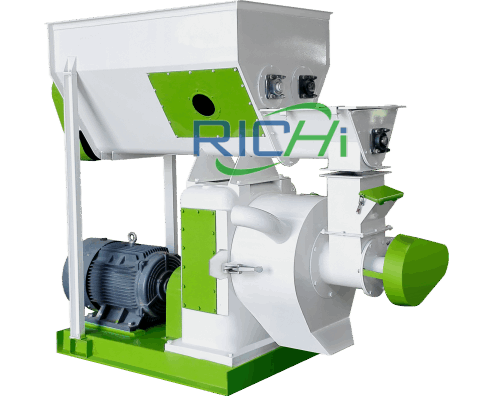

A purpose-built corn stalk pellet machine is designed to handle straw-type biomass efficiently. Compared with feed pellet equipment, it offers higher compression strength and reinforced components to cope with abrasive agricultural residues.

Key advantages include stable pellet formation, improved density, reduced fines, and consistent output. When properly configured, the machine can process pure corn stalks or blended agricultural residues, offering flexibility for different production strategies.

This adaptability makes pelletizing a practical solution for regions with seasonal biomass availability.

From Raw Stalks to Pellets: A Complete Industrial Solution

Commercial projects require more than a single pelletizer. An industrial straw pellet production line solution integrates each processing stage into a coordinated workflow, ensuring efficiency and long-term reliability.

Crushing and Size Reduction

Corn stalks are chopped and crushed into uniform particles to improve compression efficiency and protect pelletizing components.

Drying and Conditioning

Moisture is carefully adjusted to an optimal range, allowing natural binders to activate during pellet formation.

Pelletizing and Shaping

Material is compressed under high pressure, forming dense pellets suitable for industrial use.

Cooling and Screening

Fresh pellets are cooled and screened to improve hardness and remove excess fines before storage.

This integrated approach minimizes downtime and stabilizes pellet quality across production cycles.

Application Scenarios and Market Potential

Corn stalk pellets are widely used in industrial boilers, district heating systems, and biomass power plants. In regions with large corn production, they offer a cost-effective alternative to wood pellets.

Many operators use pellet fuel to reduce fossil fuel dependence while utilizing locally available resources. For investors and project planners seeking practical references and insights, exploring a knockout post can help clarify system selection and operational planning.

Choosing the Right Pellet Mill Configuration

Selecting the right pellet mill for sale involves more than capacity alone. Die specifications, compression ratio, and motor power all influence pellet quality and operating cost.

A well-matched pellet mill improves output stability, reduces maintenance frequency, and extends service life. When combined with proper upstream preparation and downstream handling, it becomes the backbone of a successful biomass pellet operation.

Long-Term Value of Corn Stalk Pellet Production

Corn stalk pellet production offers both environmental and economic benefits. It transforms agricultural waste into renewable energy, reduces open-field burning, and creates additional income streams for farming regions.

With growing demand for sustainable fuel solutions, corn stalk pellets are positioned as a practical option for biomass projects seeking scalability and long-term returns.

Conclusion

Corn stalks are no longer a disposal problem but a renewable resource with strong commercial potential. By adopting a reliable corn stalk pellet machine and a well-designed production line, producers can turn agricultural residue into high-value biomass fuel and participate in the global clean energy transition.